Oil Coolers

When an engine is assembled, the oil clearances are set with the expectation that the engine oil will have a certain viscosity when the engine is at normal operating temperature. However, if the engine oil gets too hot, the oil becomes thinner and loses its ability to prevent metal-to-metal contact. When this contact occurs, the parts wear, increasing the oil clearance. Subsequently, oil pressure drops with complete engine failure shortly thereafter.

In addition to lubrication, engine oil also helps cool the engine. Some engines use jets of oil to cool the undersides of the pistons, and oil not only lubricates but carries a significant amount of heat away from turbocharger bearings. But again, if the oil temperature is too high, this cooling capability will be lost. Overheated pistons can fail or allow engine damaging and power reducing detonation, and overheating can destroy the turbocharger bearings.

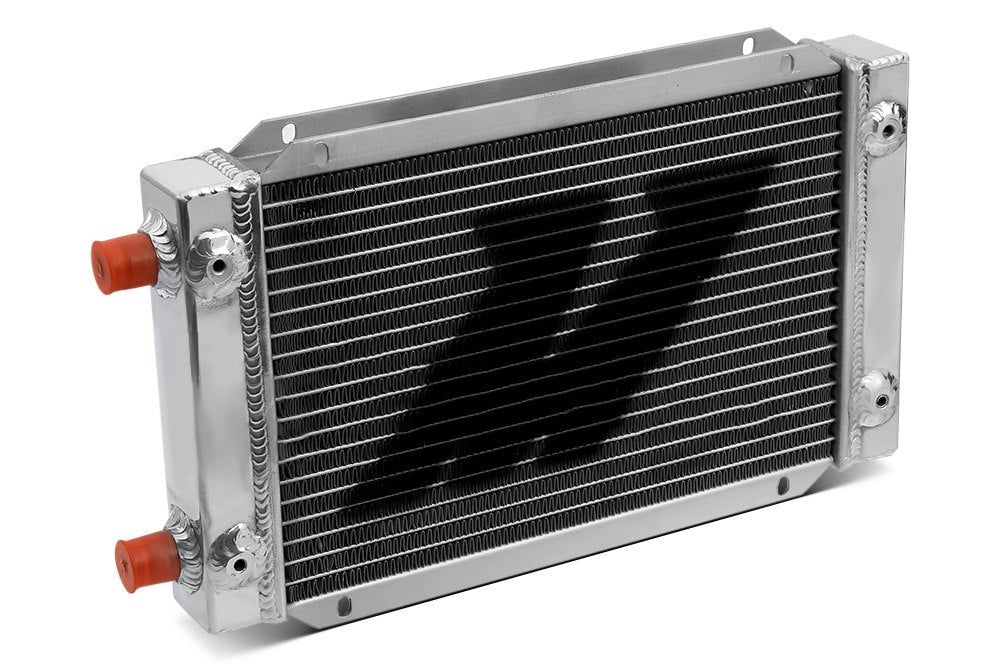

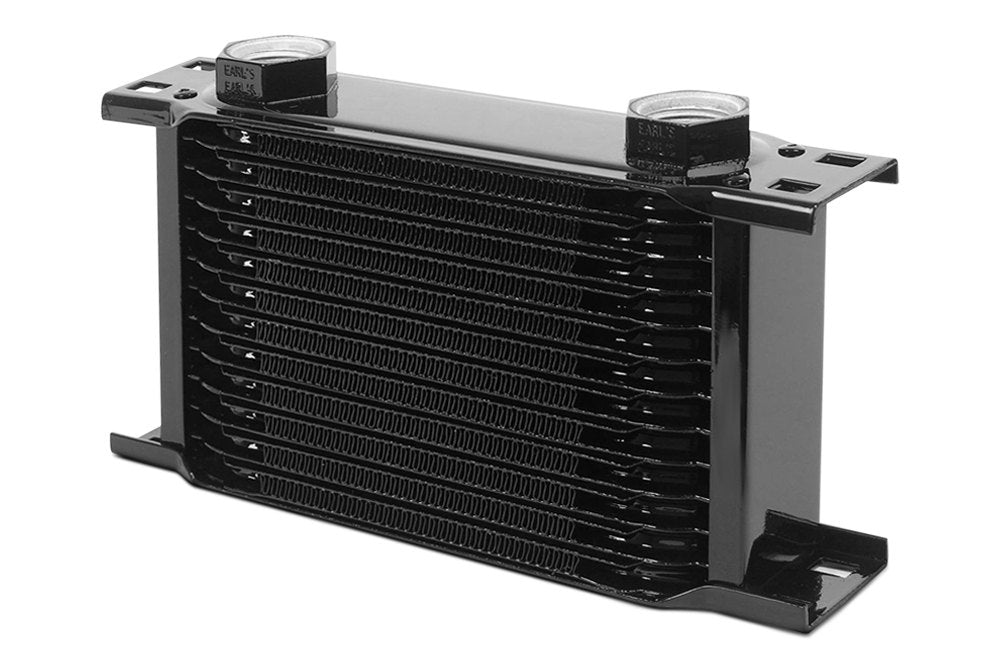

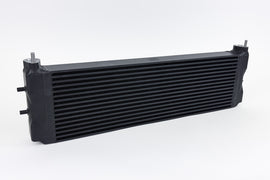

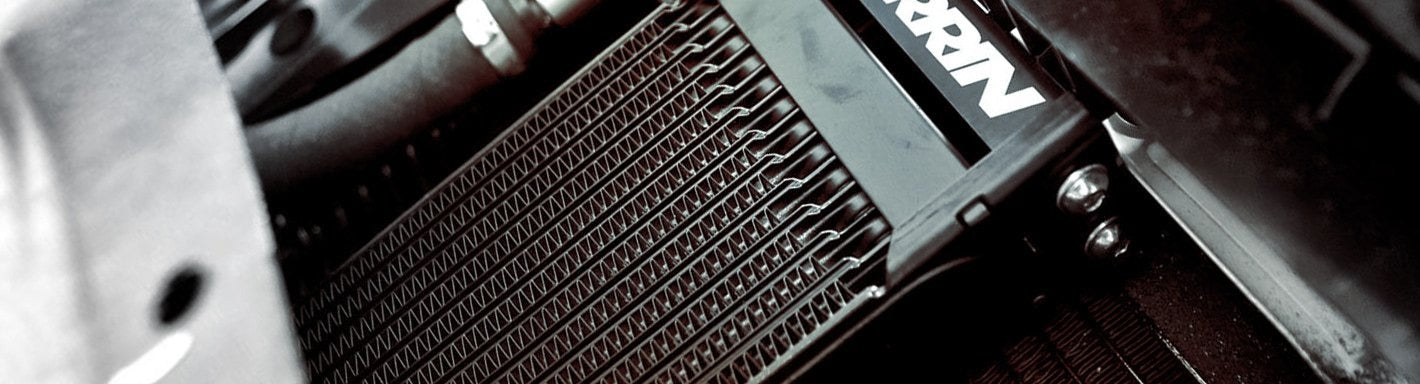

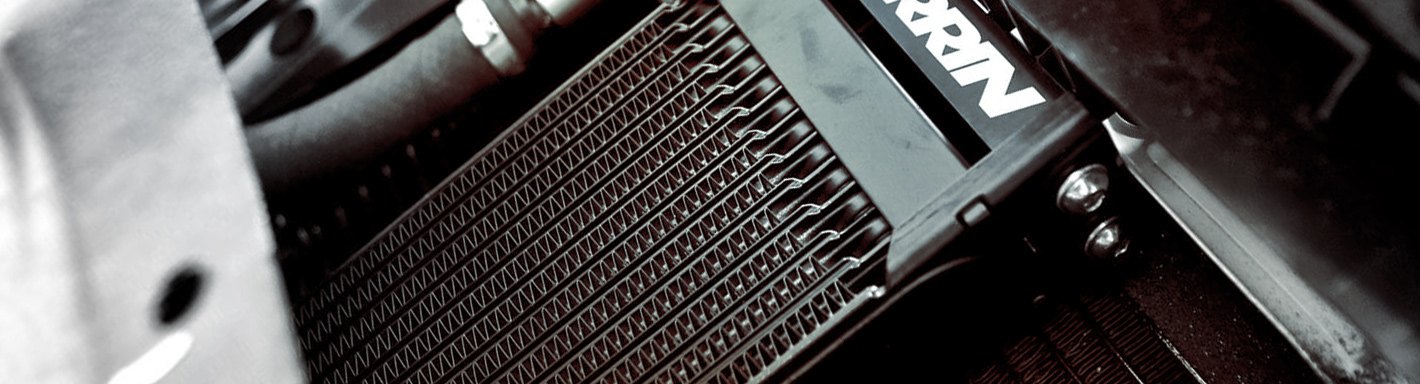

Air flowing around the oil pan is enough to carry the heat away from the engine oil on an ordinary road vehicle driven at normal highway speeds. But performance and racing engines operated at high RPMs can quickly elevate the oil temperature beyond the oil pan's cooling ability, even on deep sump and finned pans. This is when an engine oil cooler becomes necessary. An oil cooler is like a small radiator: oil flows through the cooler and transfers heat to the surrounding air so the oil can stay within its optimal operating temperature range, ensuring that viscosity is maintained and preventing oil break down.

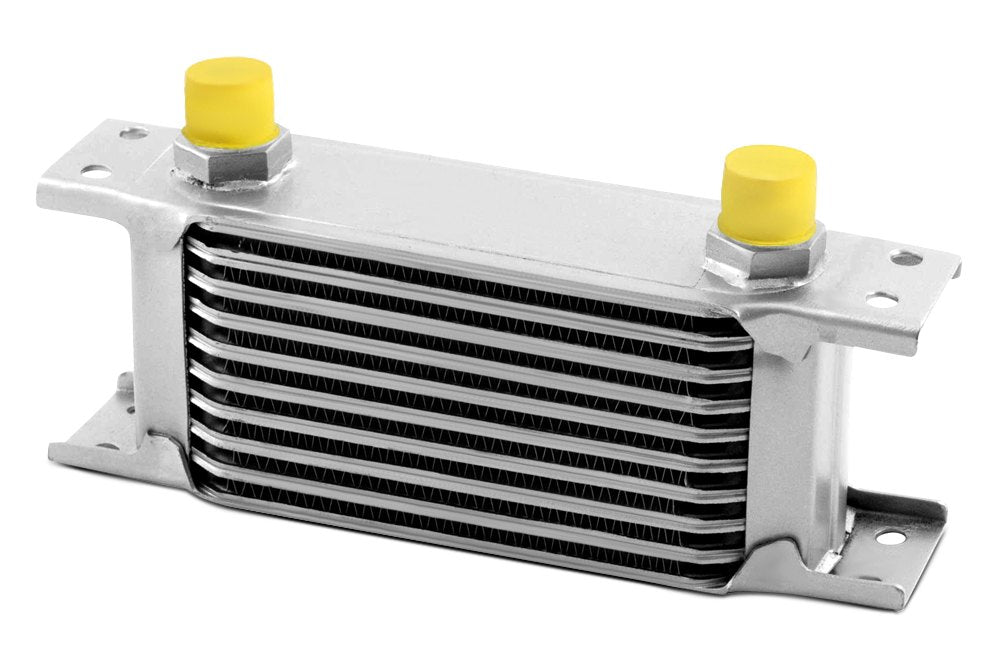

There are several types of engine oil coolers, including tube and fin, plate and fin, and stacked plate coolers. Tube and fin coolers have serpentine tubes through which the oil flows, attached to fins that transfer heat to the air. Plate and fin coolers are formed like radiators, with oil flowing through plates attached to cooling fins. Their larger surface area makes them more efficient. Stacked plate coolers are the most efficient, with larger plates than plate and fin coolers. Most coolers contain turbulators that increase heat dissipation.

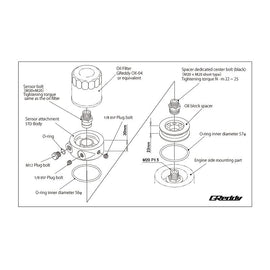

Oil coolers can also be classified by number of passes - the number of times the oil circulates the length of the cooler before exiting. More passes equals more heat dissipation. Besides the cooler, our kits generally include lines, fittings, mounting hardware, and a sandwich adapter, which mounts between the engine and oil filter. Instead of the adapter, some kits plumb the lines into an oil filter relocation mount. Ideally, the cooler should be installed where it is exposed to ample airflow. However, if you're forced to install it where there is little airflow, we offer coolers with an integral 12V cooling fan.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR