Exhaust Fabrication Components

Like the road that links your home with your driving destination, exhaust pipes provide the pathway for the exhaust gas that originates at the cylinder head and exits at the tail pipe. Along the way, the exhaust pipes also connect together all the exhaust system components: the manifold that collects the gases from each port and channels them to one outlet, the catalytic converter that converts the harmful compounds, and the muffler that quiets the pressure pulses. From header pipe to tailpipe, and everything in between, we have all your exhaust pipe needs.

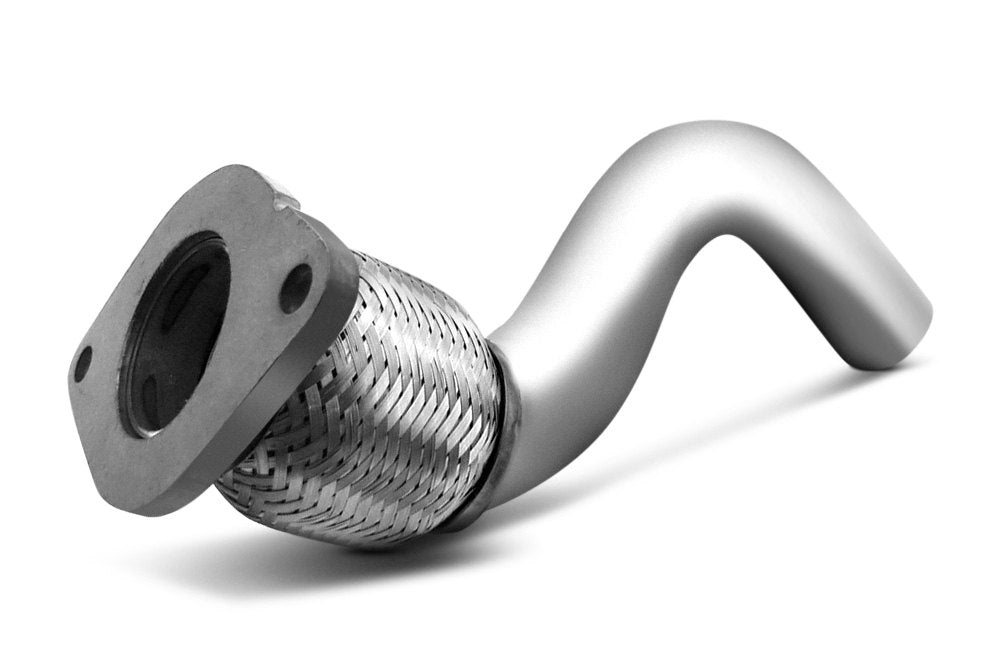

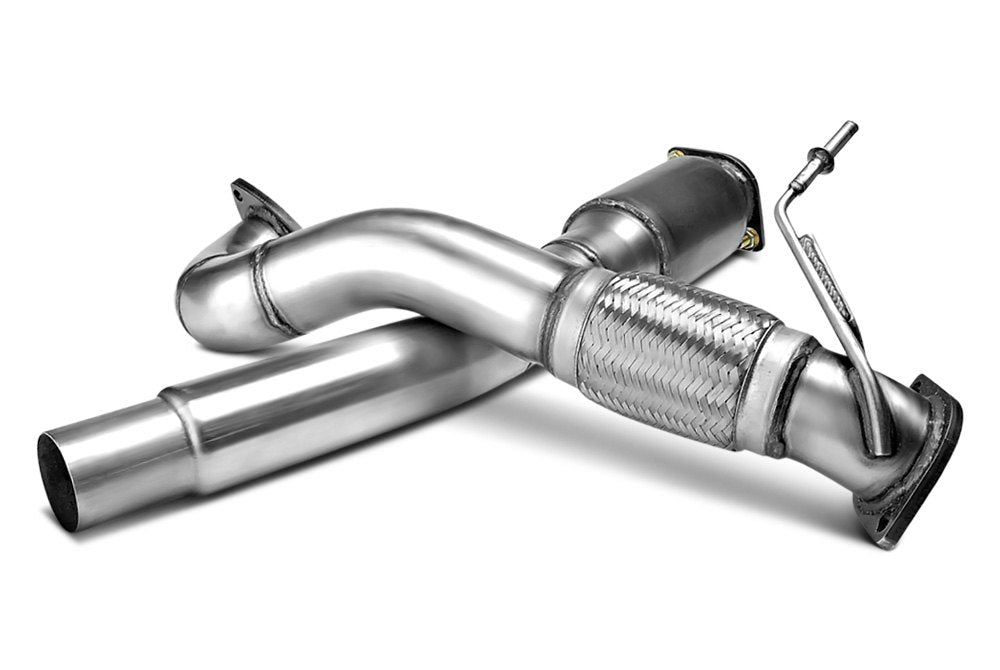

The header pipe (sometimes called a down pipe) connects the exhaust manifold with the catalytic converter on in-line engines, while V-type engines with two manifolds have a Y-pipe. On some applications the manifolds are connected by a crossover pipe, and a header pipe is connected to one of the manifolds. An intermediate pipe connects the catalytic converter to the muffler, and the tail pipe connects the muffler to atmosphere at the rear of the vehicle. In addition to the above, exhaust systems can also include extension pipes, flex pipes, and tail spouts or exhaust tips.

Exhaust pipes are subject to rust caused by exposure to the elements and road salt. Severe rust can result in perforation of the pipe and an exhaust leak. It's also common for rust to cause a pipe to break at a weld or connection point. Pipes can also rust from the inside, especially on vehicles driven short distances in cold weather. The pipes never get hot enough to evaporate condensation, and the moisture combines with chemicals in the exhaust to create corrosive compounds that erode the metal. In their position on the underside of the vehicle, exhaust pipes can also suffer impacts from obstacles and road debris that could cause physical damage. Some pipes have double wall tubing and in some cases the inside can collapse causing a restriction, with no visible problem on the outside.

A perforated or broken pipe must obviously be replaced to keep noise to a minimum, but more importantly to prevent the possibility of exhaust gas entering the cabin. The exhaust gas produced by an internal combustion engine contains poisonous Carbon Monoxide (CO), which in sufficient concentrations can cause severe illness and even death. Exhaust pipes can be connected with clamps, bolted together at joints sealed with a gasket, or welded. Each connection should be inspected for integrity and leaks. Some pipes have integral hangers and if broken the exhaust system could hang or contact other components. A collapsed or dented pipe can be checked for restriction using a vacuum gauge and tachometer. If vacuum drops while the engine is held at 2500 rpm for 15 seconds, the system is restricted.

No matter the cause of damage or reason for replacement, we can supply you with exhaust pipes that will make your system whole again. These aren't universal tubes that have to be ""massaged"" to fit, but pipes that are exact equivalents of original equipment. Each of our pipes is specifically designed for the application and is a replica of the factory installed pipe. The pipe diameter is the same to maintain exhaust flow and performance, the pipe bends are precision made to exactly duplicate the factory routing, and the connections are the OE type. If pipe mount or hanger connections are part of the OE design, they will be configured properly and in the right place for seamless installation. Our pipes will fit and connect properly and deliver OE level performance.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR