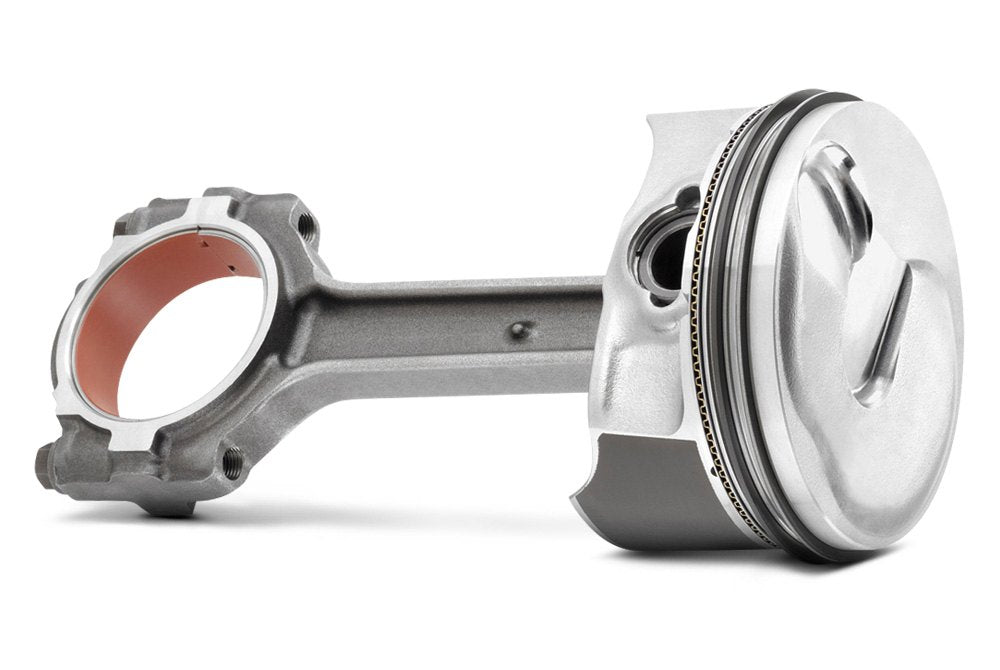

Pistons, Rings & Connecting Rods

In any internal combustion engine the pistons have to withstand the tremendous heat and pressure of combustion. The piston rings must also endure this extreme strain and temperature while sealing the pistons to the cylinder walls and providing sufficient oil control. Finally, the connecting rods must persevere through the pounding as they transform the pistons' reciprocating motion into the rotational movement of the crankshaft.

These stresses are amplified in a high horsepower performance engine, which typically has higher compression, operates at higher RPM, and may have power adders like nitrous oxide, a turbocharger or supercharger. It goes without saying that stronger pistons, rings, and connecting rods are necessary, but at the same time these parts should be as light as possible to allow the engine to rev freely, while creating very little frictional power loss.

Factory connecting rods are typically made of cast iron or powdered metal, and aren't adequate for performance use. Most performance rods are manufactured from forged or billet steel, and there are aluminum rods for drag racing. You'll find forged rods in I-Beam and H-Beam construction, with the latter generally providing higher strength with less weight. Performance rods are precision made, with uniform center-to-center dimensions, weights, and bore concentricity. They also are commonly bushed for floating pins, have stronger and larger diameter rods bolts, and are available in lengths to suit the desired rod ratio.

Performance piston material ranges from cast hypereutectic (an alloy with a high silicon content for strength) aluminum that is fine for mildly modified street engines to forged and billet aluminum for high horsepower and racing applications. All pistons are designed and precision machined for superior strength with light weight. Factors that affect piston selection include bore size, compression ratio, and valve clearance. Most pin bores are designed for floating pins retained by clips. Many pistons come with coatings to reduce skirt scuffing, improve surface wear resistance, and reflect heat, which improves durability.

The modern trend in performance piston ring design is for thinner rings, with some of the latest ring packs featuring 1mm top and 2nd rings, and 2mm oil control rings. Thinner rings create less friction while at the same time conforming to the bore better for improved sealing and superior oil control. To ensure durability these rings are made from steel or ductile iron and the compression rings receive a plasma-moly, chrome, or proprietary coating to resist heat and wear. The ring face may also be lapped for faster break-in. Besides less drag and lower weight, thinner rings also allow more options for piston design.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR