Crankshafts

No other engine component is subject to as much stress as the crankshaft. It's impacted by the explosive force of combustion thousands of times every minute, yet typically will provide many thousands of miles of trouble free service in an unmodified engine. But, hop up the engine for increased horsepower and high RPM use, and that once reliable stock crankshaft can become the pin and your precious engine a very expensive hand grenade.

Many OE cranks are made of cast iron, which is reliable at factory power levels, but isn't up to the demands of a performance engine. Also, the constant pounding can cause hard-to-find hairline cracks to develop, and may even cause the crank to bend. If the journals are worn, regrinding may remove the surface case hardening. Don't run a used OE crank and risk blowing up your engine. Be safe, and make a new performance crankshaft the cornerstone of your build.

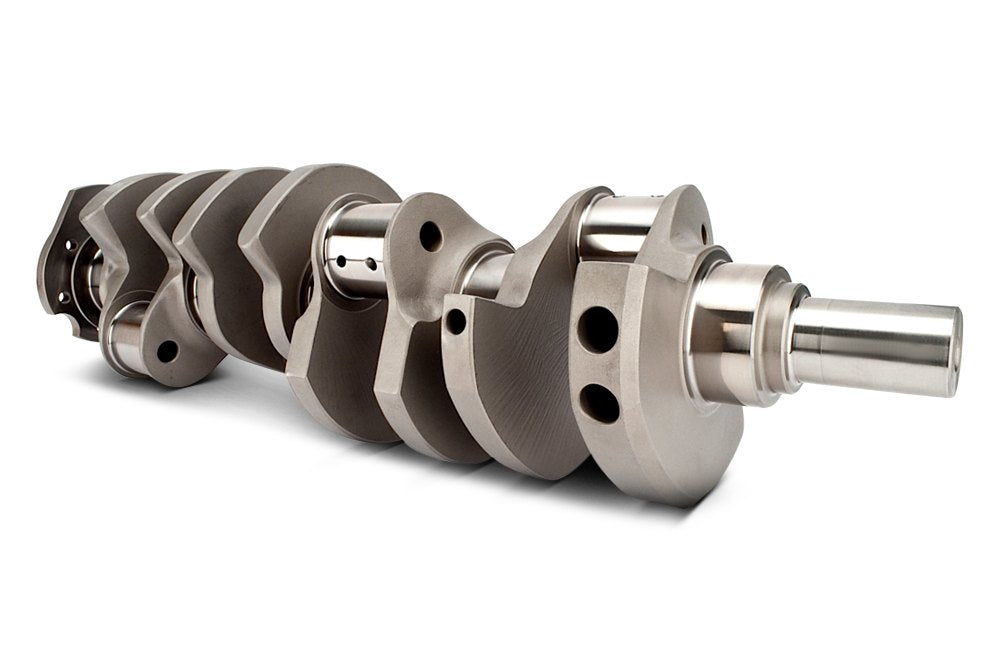

We offer performance crankshafts for all popular engines, designed and manufactured by performance crankshaft specialists, in materials and configurations for every use and horsepower output. Cast steel cranks are relatively inexpensive yet can handle some serious power. Next up the ladder in strength and price are forged followed by billet steel cranks. Forged cranks are created by pressure forming heated steel in a die, while billet cranks are CNC machined from solid steel. Regardless of the material, all performance cranks are finish machined to a greater degree of precision than standard replacement cranks.

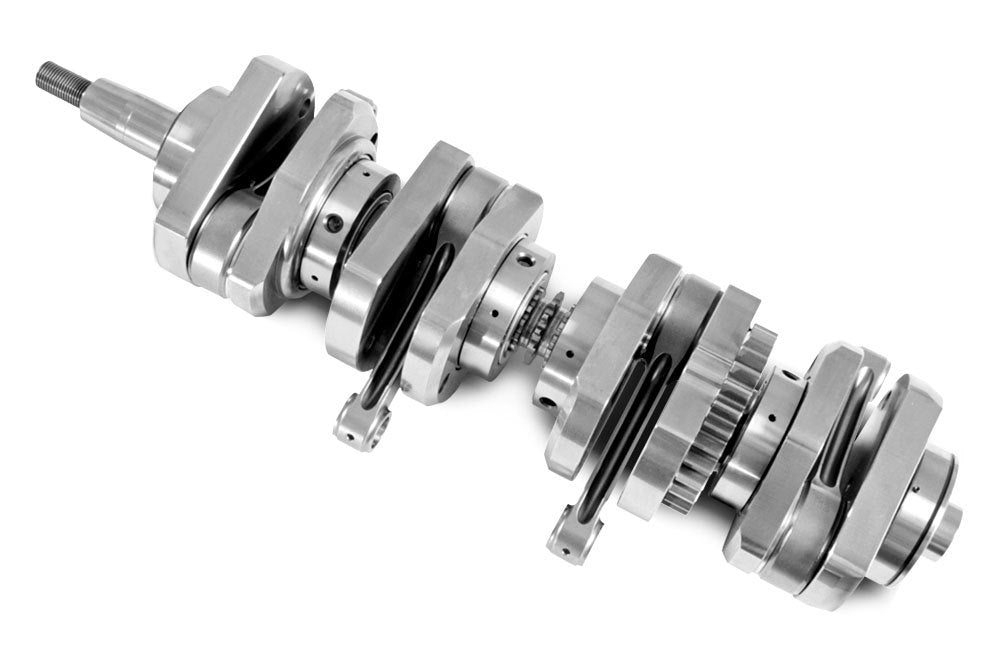

Although the specifics will vary according to application and price, features that you'll commonly find on performance crankshafts include micro-polished journals to eliminate friction, chamfered oil holes to remove sharp edges and improve lubrication, larger fillet radiuses to prevent cracks, and surface hardening by heat treating or nitriding to increase strength. Some performance and racing cranks have the counterweights radiused and knife edged to reduce windage and drag, and they're often lightened to enable faster revving by cutting down the counterweights and drilling the center of the main and rod journals.

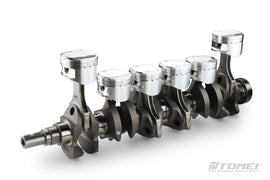

If you're starting from scratch with a new crank, on some engines you can do more than ensure the bottom end stays together - you can add substantial horsepower too by increasing displacement. Engine size is determined by bore and stroke, and while there is usually only enough meat in the average block to increase the bore by 0.060"", the stroke on some engines can be fattened by as much as 0.400""! We offer ""stroker"" cranks to increase the stroke and displacement of many popular engines, as well as fully balanced rotating assemblies that include the crank, bearings, connecting rods, pistons and rings.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR