Ball Joints

The ball joint is the articulating connection between the control arm and the knuckle/spindle. It allows the assembly to move vertically in response to road and suspension movement, while at the same time enabling the knuckle/spindle to pivot horizontally as the vehicle is steered. OE ball joints are designed for the stresses and operating angles of typical street driving, on a vehicle with factory spec ride height, but they're inadequate for the demands of racing and spirited performance motoring, and frequently can't accommodate the alignment requirements of lowered cars and lifted trucks.

A performance ball joint must have several important qualities. It should have the strength and premium features to reliably perform under severe operating conditions, and maintain precise operating clearances without causing excessive friction that could affect steering and suspension response. And because the ride height of performance vehicles is frequently altered, some applications must have adjustable features to accommodate the change in suspension geometry. All of these advantages can be found in the performance ball joints on our digital shelves.

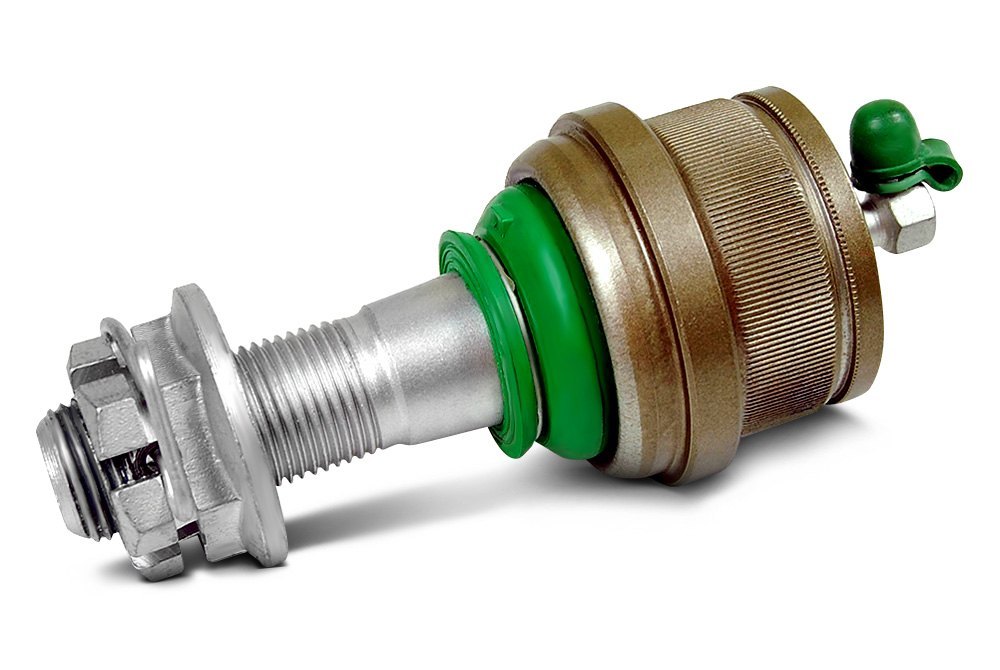

To consistently handle the forces imposed by racing and high speed driving, especially over rough terrain, performance ball joints are typically constructed from premium materials and have forged steel housings and chrome moly steel ball studs. Many have metal bushings instead nylon and are greasable to ensure dependable operation under the toughest conditions. The dust boot may be constructed of premium material like polyurethane and be retained by an external metal sealing ring to make sure it and the lubricant contained within remains on the joint for long component life. To operate effectively with the increased range of suspension movement typical of racing and high speed driving conditions, especially off-roading, performance ball joints commonly have high ball stud articulation angles.

All ball joints have designed in operating tolerances for the ball stud within the ball joint housing. If clearance is excessive, it can cause noise, and steering response and handling can be negatively affected. However, a joint that is too tight and has excessive friction can bind, which can also adversely affect steering and handling. Performance ball joints typically produce less friction and operate more smoothly than their OE counterparts, and the preload on some performance ball joints is adjustable to set the level of friction. And for selected severe duty applications we offer fully rebuildable performance ball joints. You'll never have to replace the entire ball joint no matter how much it's been abused and you'll always have the exact level of tension you want.

When vehicle ride height is altered, such as when a car is lowered or a 4WD truck is lifted, suspension geometry can be changed to the point where the OE alignment adjustment features can't provide the desired camber and caster settings. Some performance ball joints are specially designed for specific applications to provide the desired adjustability. This may be in the form of an offset housing, an eccentric ball stud, or the position of the ball joint may be moveable on the control arm. Roll center can be significantly changed when a car is lowered, resulting in traction loss and poor handling. Performance ball joints with longer extended ball studs can be used to correct roll center height, and several length studs are available for some rebuildable ball joints.

In addition to the above, we offer much more to satisfy your performance ball joint needs. If not so equipped you can upgrade your ball joints with durable, wear-resistant polyurethane boots, some available in your choice of red or black. Our performance ball joints come with bolt-on, screw-in, and press-in housings, for upper and lower, and front and rear installations, but for custom fitments we also have adapters, holders, and weld-on sleeves. We also carry ball joint installation kits, and removal, installation and inspection tools. And along with replacement ball studs and housings, of course we have the rebuild kits needed for rebuildable ball joints that include wear components like bearings and seals, as well as commonly replaced parts like castle nuts, retaining clips and cotter pins.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR