Balance Shafts

Categories

During engine operation, there are several forces created that affect engine balance and result in vibration: The rotating mass of the connecting rod and piston at the offset crank throw and the crankshaft counterweight, the up and down reciprocating forces of each piston and connecting rod in the cylinders, and the forces created when each cylinder is fired. These forces can be countered by engine design or the use of balance shafts.

The number of cylinders, engine configuration, and the point at which the cylinder fires all play a part in how well an engine is balanced. For example, a typical V8 engine is well balanced because the angle between the cylinder banks is 90 degrees, and a cylinder fires every 90 degrees of crankshaft rotation. Flat engines are perfectly balanced because the forces in each cylinder bank cancel each other out, and the engine fires every 180 degrees.

However, some engines, notably 4-cylinder in-line and V6 engines, have forces that can't be counteracted by design alone, and this resulted in some engines produced in the past that had a reputation for high levels of roughness and vibration. Vehicle manufacturers have employed various methods to limit the effects of vibration, including soft motor mounts, and using 60 degree bank angles or split-pin crank throws on V6 engines, but the most common solution to the vibration problem has been the installation of balance shafts.

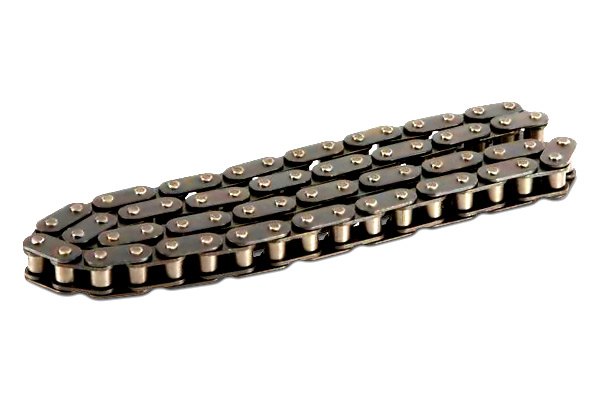

Balance shafts have eccentric weights that counteract the forces in the engine that create vibration. Like the camshaft, balance shafts must be perfectly timed with the rotation of the crankshaft for them to be effective. An engine will have one or more balance shafts, with most 4-cylinder engines having two, and V6 engines with one. Balance shafts can be driven by a chain or belt. Both use tensioners to maintain belt adjustment. Belt arrangements usually include an idler pulley, and chain layouts have chain guides.

Balance shaft belts and chains can suffer from the same symptoms as their cam drive counterparts. Belts should be periodically replaced and because removal is generally required to access the timing belt, the balancer belt should be replaced at the same time. Balance shaft chains can elongate and timing can be thrown off, which can result in vibration. No matter what kind of balance shaft setup you have, we have the replacement parts for the job including belts, chains, sprockets, tensioners, pulleys, guides, seals, and gaskets. All parts are made to OE specs so you can be assured of precise fit and perfect function.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR