Timing Gears, Chains & Covers

Lining up the timing marks on the cam and crank sprocket will suffice when building a stock motor, but that degree of accuracy isn't good enough on a performance engine. The marks on some timing sets can be off by 2 or 3 degrees, which may not sound like much, but such deviation can reduce engine output by as much as 50 horsepower! A performance cam should be set with a degree wheel upon installation, and there must be a means to adjust the cam timing.

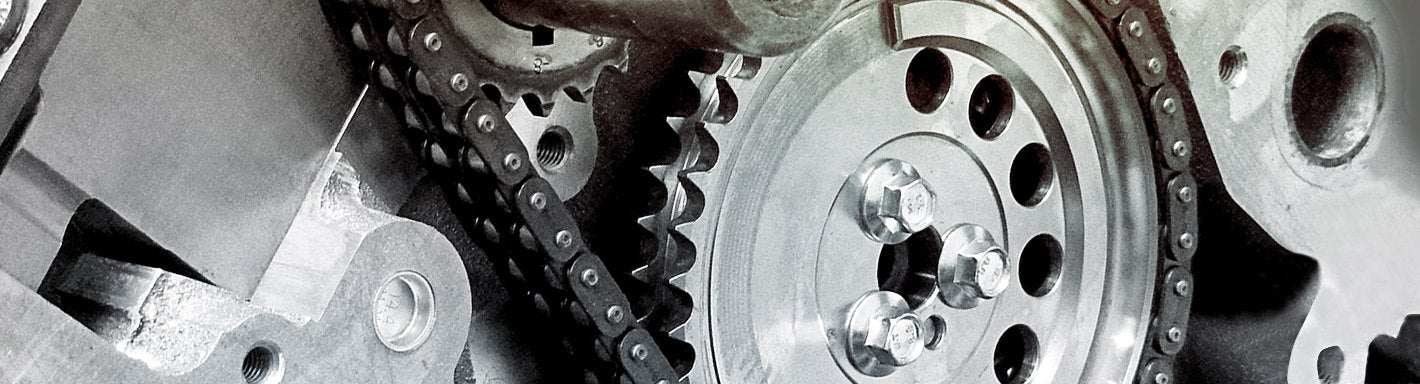

But careful assembly will all be for naught if the timing components wear and allow cam timing to go astray. Soft aluminum or composite nylon cam sprockets and inverted silent tooth timing chains may provide quiet operation, but they can wear easily and retard cam timing. Heat-treated iron or billet steel sprockets with single or double row true roller chains are not only more durable to maintain timing accuracy but they also reduce frictional power loss.

We offer quality roller timing sets with various means to adjust cam timing. Some have a choice of keyways in the crank sprocket, while others have offset bushings or slots for cam sprocket adjustment. This not only enables you to set the cam to the manufacturer's specs, but you can advance or retard cam timing to suit where you want to make power. In general, advancing the cam opens the intake valve sooner for more low-end torque, and retarding it closes the intake valve later for more high RPM power. We also have quick access timing cover setups to make adjustment easy.

If you're looking for even greater durability and timing accuracy, consider converting your chain and sprockets to a gear drive or belt drive arrangement. A gear drive setup has a cam and crank gear with one or two idler gears. The possibility of chain stretch is eliminated, for consistent cam timing, plus you get a characteristic blower-like gear whine. Belt drives offer infinite adjustability for accurate cam timing, plus the belt absorbs crankshaft harmonics and vibration. Offered for both wet and dry installation, belt drives also deliver increased durability while creating less frictional loss.

Although most of our performance cam timing offerings are for OHV applications, there's no need to feel neglected if you have an OHC or DOHC engine. Here you'll find CNC machined cam gears for both timing chains and belts with laser-etched timing marks for precise cam timing adjustment. These gears are made from high grade billet aluminum for light weight and durability, and hard anodized to prevent wear. We also have heavy-duty chain tensioners for selected applications that eliminate chain slack even under low oil pressure conditions, and two-piece timing covers that allow easy cylinder head removal.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR