Fuel Injectors & Rails

Modern electronic fuel injection systems have a degree of designed-in adaptability. This means if you want to increase airflow and horsepower by adding a cold air intake and performance exhaust system, the fuel system can compensate for the additional airflow and provide more fuel to ensure your engine has the right air/fuel mixture for all operating conditions. However, when airflow is significantly increased, then fuel flow must also be enhanced to increase horsepower and avoid a dangerous lean condition.

Adding a supercharger or turbocharger, increasing engine displacement, reducing exhaust restriction with headers, and installing a larger throttle body, high flow intake and cylinder heads, and performance camshaft, will all increase airflow through an EFI engine. Installing performance fuel injectors will ensure that fuel flow is proportionately increased, so you can realize the desired gain in horsepower. From mild hop-ups to full race applications, we have the performance fuel injectors for the job.

Performance fuel injectors are classified according to resistance and flow rate, in lbs. per hour or cc's per minute. The resistance of high impedance, or saturated, injectors is 12-16 ohms, while low impedance, or peak & hold, injectors range from 0.5-6 ohms resistance. Injector impedance must match the ECM injector driver, and most OE ECMs are set up for saturated injectors. Flow rate can be calculated by multiplying horsepower by Brake Specific Fuel Consumption (BSFC) and dividing by the number of injectors multiplied by the duty cycle, which is normally not over 80%, at a static 43.5 psi fuel pressure. BSFC is approximately 0.50 for naturally aspirated engines and 0.60 for forced induction engines.

Using the above formula, a naturally aspirated 700 horsepower V8 engine will need injectors that flow at least 55 lbs/hr or 578 cc/min. We offer direct fit and custom performance fuel injectors for gasoline, E85, and racing gas. Our direct fit injectors combine the increased flow you need with easy installation. They're made to fit correctly into the manifold and fuel rail and allow easy fitment of the injector harness, the impedance is matched to the driver circuit, and they're flow matched to ensure each cylinder gets even fuel distribution. Details like valve geometry and intake manifold design are also taken into account so you get optimal injector spray pattern and fuel atomization.

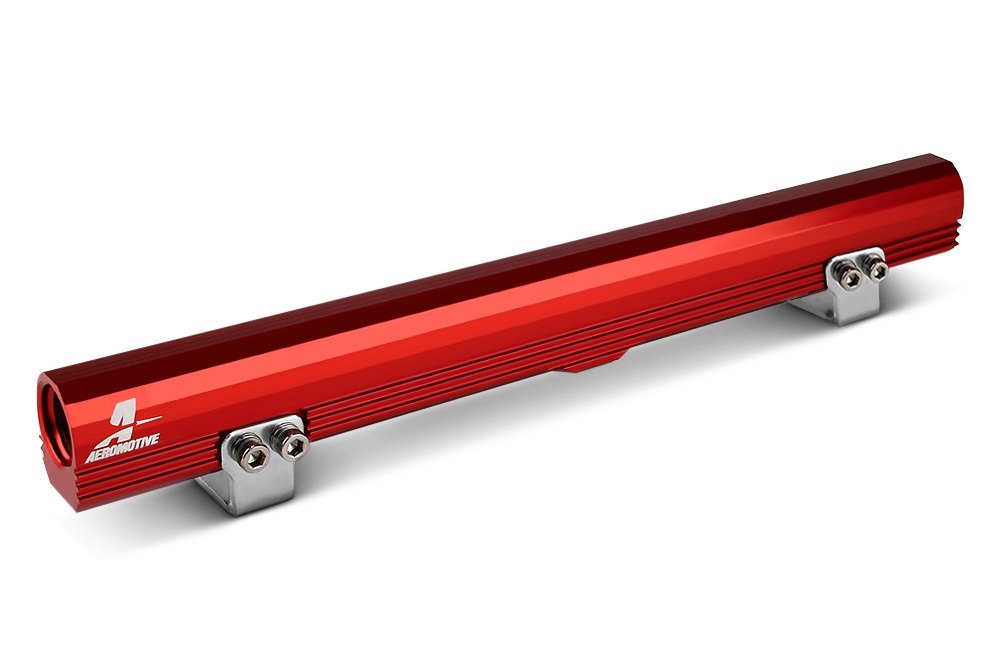

Our selection of custom injectors includes both saturated and peak & hold injectors in a wide range of flow rates. When upgrading to significantly larger fuel injectors you'll need to provide a corresponding increase in fuel flow, and we have the fuel rails, fuel lines & fittings, and high flow fuel pumps to ensure your injectors get an ample supply of fuel. You'll also need to reprogram or upgrade your ECM to take full advantage of your injectors, depending on flow rate, horsepower and whether you're building for the street or the track. We have a complete line of programmers as well as programmable engine management systems for select applications that plug right into the factory wiring harness.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR