Turbocharger Wastegates

Most modern-day turbochargers are small-sized devices which provide a quick power boost even at low engine speeds, making it possible to eliminate the major turbocharger's drawback - a turbo lag. However, there is the other side of the coin. A smaller turbocharger is vulnerable to higher exhaust pressure which can damage its housing if not maintained within safe limits. To keep this under control is the job of a turbocharger wastegate. It is a boost control device that bypasses some exhaust flow from the turbocharger's turbine and redirects it to the exhaust system, preventing turbine damage and an excessive power boost.

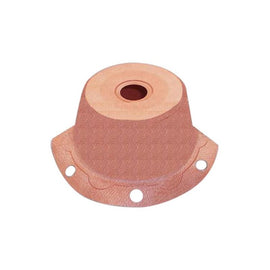

All turbocharger wastegates can be divided into two major types, including internal and external ones. Internal wastegates come in the form of a built-in bypass valve that is developed and designed to handle stock boost levels. In its resting position, the valve is closed, allowing for full exhaust flow through the turbine. However, when the pressure exceeds a specified limit, the force that is created opens the valve that routes some gases to the catalytic converter through a hollow passage in the turbocharger's housing. As soon as the pressure reduces to a safe limit, the valve closes and the process repeats.

The majority of large frame and high-performance aftermarket turbochargers are not equipped with an internal wastegate. They rely on its external counterpart which provides significantly better control of high boost pressure. External wastegates have bigger inlet and outlet ports as well as stronger actuator diaphragms and springs. They can be operated and controlled in several different ways, including the use of a traditional actuator, an electric solenoid or electric actuator. The latter is the most advanced and precise method of wastegate control since it involves the use of the PCM that adjusts the position of the wastegate valve.

BUY NOW, PAY LATER. Starting at 0% APR

BUY NOW, PAY LATER. Starting at 0% APR